Creating Loudspeakers for Orion Spacecraft

Since 2017, MISCO has been developing loudspeakers for NASA's Orion spacecraft, a key component of NASA's deep-space exploration efforts. Designed to withstand some of the most extreme conditions, these loudspeakers play a crucial role in ensuring astronauts have reliable audio communication on their journey to the Moon and, eventually, Mars.

Meeting NASA's Rigorous Standards

Meeting NASA's requirements for reliability, durability, and performance under extreme conditions is no small feat. Each component must meet the highest standards to ensure mission success and astronaut safety.

So, how resilient does the loudspeaker in Orion need to be?

"It has to be able to withstand 4,000 Gs," says Rich Field, Chief Engineer at MISCO, who led the project. "And it has to withstand that force along multiple axes and still be able to perform during and after that impact. It's an example of the 'margin on margin' thinking that is critical to assure the success and safety of each NASA mission."

MISCO prides itself on designing robust loudspeakers and conducting extensive testing. However, developing and testing a loudspeaker capable of withstanding four thousand times the strength of gravity was a new challenge for MISCO.

"They do what's called a pyroshock test," Rich explains. "They use a steel beam with an explosive charge on one side and put an object on the other side to represent the loudspeaker. They detonate the explosive and then confirm it created enough force. Then they strap the real loudspeaker on and do it again."

This test simulates the extreme conditions of a rocket launch or a potential emergency mission abort. After the test, the loudspeaker is examined for any damage or loosening of parts and must meet all its original electro-mechanical-acoustical specifications.

Out of this World Engineering

MISCO engineers specialize in addressing unique acoustical challenges for customers on Earth. However, in space, the challenges become vastly different due to environmental factors such as zero gravity, fluctuating air pressures, and extreme temperatures. For instance, loudspeakers create sound by exerting force on air to generate localized variations in air pressure—essentially, sound waves. A sudden drop in air pressure aboard the Orion spacecraft could be life-threatening, and astronauts must be able to hear a loss-of-pressure alarm even if they are asleep.

The lower air pressure presents a distinct challenge for loudspeakers, which must function effectively under these conditions while still producing the required sound level in 9 PSI, along with the standard 14.7 PSI found at sea level on Earth. Modeling and measuring loudspeaker performance in various atmospheric conditions was a novel challenge for MISCO. Extensive modeling and calculations were carried out to demonstrate that the selected loudspeaker design would perform reliably, which was later validated through customer testing in pressure chambers.

These environmental challenges compelled MISCO to address every aspect of the loudspeaker's construction, including the materials used, to ensure they could endure the harsh conditions of space.

"We had 1,600 lines in our logbook related to issues on this project. Each line represented something we had to check, tweak, and resolve. That's significantly more than any other project we've worked on," says Rich. "For example, we dedicated a considerable amount of time and resources to finding the right adhesives for the speaker."

MISCO faced significant material challenges, as each component needed to meet operational requirements across all conditions and environments. NASA maintains a special list of approved materials, each rigorously tested and verified for use in space, which adds further complexity to material selection. The commercial-grade epoxy typically used by MISCO for many of its loudspeakers was not included on that list. To address this, MISCO collaborated with a specialized supplier and leveraged its decades of loudspeaker-building expertise to develop a solution that could meet the pyroshock and temperature requirements of -40°C to +85°C.

MISCO’s Expertise and Innovation

MISCO was chosen for the Orion project due to its extensive experience with loudspeakers designed for military applications and its Oaktron division, which had previously developed loudspeakers for the International Space Station (ISS). This background in robust, high-reliability designs made MISCO an ideal fit to meet NASA's stringent requirements for deep-space exploration.

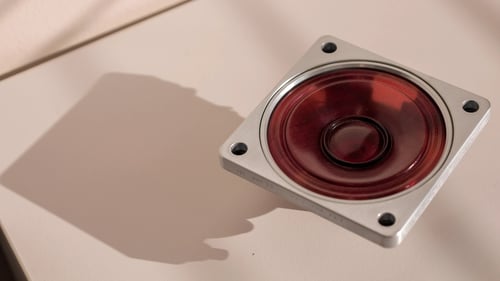

As the Orion project progressed, new challenges arose. The need for more equipment and laboratory space meant that the loudspeakers for Orion must be smaller than those used on the ISS. This added complexity necessitated a focus on innovative design to meet strict size and performance requirements while ensuring redundancy. Smaller loudspeakers, with their reduced diaphragm size, posed significant challenges for sound output, as they are less effective at interacting with the surrounding air.

The Orion loudspeaker incorporates two identical transducers for redundancy, providing the reliability necessary for deep-space missions. This redundancy is especially vital given the long distances involved—after all, you wouldn't want your sound system cutting out when you're 35 million miles away from home! Mars, at its closest, is about that far away, making reliable communication absolutely crucial. Each transducer utilizes a powerful neodymium magnet to optimize output while minimizing size and weight, effectively addressing both performance and spatial constraints.

Countdown to Orion Liftoff

The Orion spacecraft was launched into space for the first time atop the Artemis I rocket in November 2022—the most powerful rocket NASA has ever used. Since this mission did not carry astronauts, MISCO's loudspeaker was not yet installed inside Orion. Without a human crew, the communication system requirements were simplified, allowing NASA to focus on testing other critical systems.

"They told me to pencil in 2025," says Rich. "That's when Orion is scheduled to fly around the Moon with people in it for the first time."

Everyone at MISCO will be cheering on each launch and taking pride in our role in advancing space exploration.

Sometimes, the work MISCO does truly is rocket science.

Partners for Advanced Audio Solutions

Finding the right audio solutions for aerospace and aviation applications requires a partner with deep expertise and decades of experience. With over 75 years in the industry, MISCO brings unparalleled knowledge to the design and production of high-quality, reliable audio systems built for demanding airborne environments.

MISCO provides a wide range of engineering services tailored to the strict standards of the aerospace industry. Our engineering team performs thorough testing throughout the design process to ensure that every component meets the necessary performance, safety, and durability requirements for aviation and space applications. Our stringent end-of-line testing guarantees that every product we deliver meets the highest levels of reliability.

Additionally, we provide a complete catalog of off-the-shelf solutions that help save time and resources without compromising on quality or performance—ideal for aerospace and aviation applications where reliability is paramount.

If you're seeking a trusted partner to develop high-quality audio solutions tailored for aerospace and aviation environments, contact MISCO today. Our team is ready to assist you in finding the best solution to meet your project's unique challenges.

Image credits: NASA/Joel Kowsky, NASA/Rami Daud