OEM Speaker Design: Loudspeaker Testing & Verification [VIDEO]

Getting great sound starts with a great loudspeaker. This may seem simple enough, but the process to get there isn’t. Once you think through the design considerations your speaker needs to meet, it is imperative that the driver be assembled with the right, high-quality components and materials in order to get great sound and long life out of your speaker. After this, the driver still needs to be tested, measuring a number of different parameters to ensure it is performing the way you expect it to.

Designing and Building a Loudspeaker Video Series

The idea behind this video series is to give customers a close-up look at what goes into designing, building, and testing a speaker at MISCO. The fourth video in the series details the two initial phases of testing that the driver undergoes. You can see the final system testing in the next video of our series as well as the previous videos in this playlist.

The series shows the component choices made when constructing one specific 5.25” subwoofer, but the principles apply broadly to almost any speaker project.

Testing and Verification

The extent of testing for some speaker companies is usually just a quick baseline test called the Rub-and-Buzz test, measuring for audio defects due to an off-center voice coil, loose particles floating within the speaker’s magnetic gap, or excess glue somewhere in the build. The tester listens to make sure it’s about loud enough and doesn’t sound bad. This style of testing can be subjective and prone to human error.

Both qualitative and quantitative tests should be performed to make sure a speaker sounds great, meets engineering specifications, and is built to last. Every driver should go through two sets of testing before the enclosure is even built, and then once again when the loudspeaker system is fully assembled and complete.

Klippel Testing

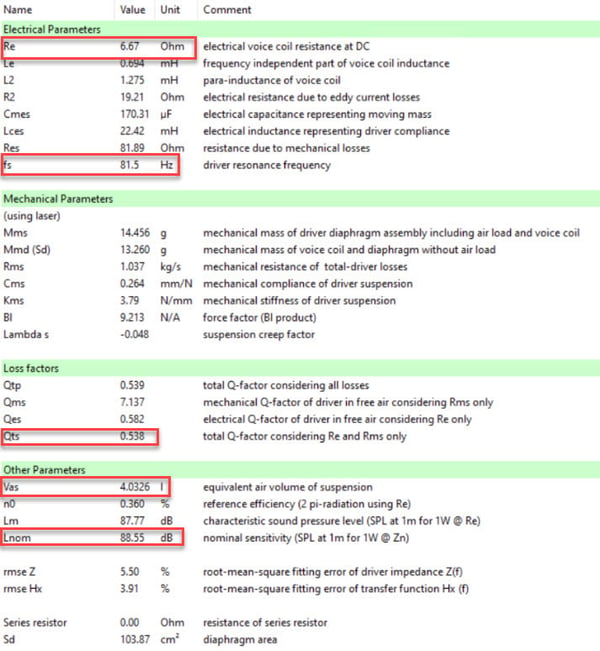

When designing a speaker, Klippel technology is used to verify the electromechanical and acoustical parameters of the loudspeaker design. A laser can measure with pinpoint accuracy exactly how the cone is moving. Warkwyn, the testing and measurement division of MISCO, operates the most fully-equipped independent Klippel analysis lab in North America. The small signal parameters (or lumped parameter measurements) of these Klippel tests include data engineers use to ensure consistency across products, such as: the DC resistance of the coil, the Qts, the VAS, the sensitivity, the BL, and more (see below).

For parameter averaging, oftentimes MISCO builds three or more samples to get a range of output data so they know what to expect from very slight variations that may occur during manufacturing.

Resource: Guide to Audio Acronyms

End-of-Line Testing

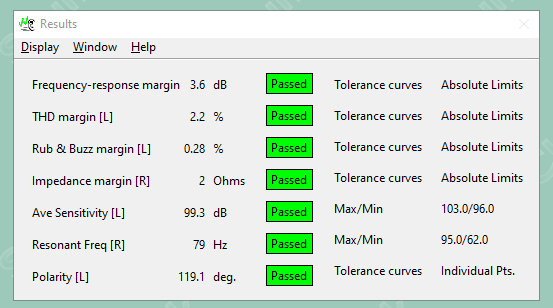

The second phase of testing comes at the end of the assembly of each speaker (before it goes into its final enclosure). End-of-line testing at MISCO covers seven different parameters: frequency response, total harmonic distortion, rub & buzz, impedance, sensitivity, resonant frequency, and polarity (see below). A driver must pass every one of these to move on to final production.

This level of testing is unique to MISCO. It ensures speakers are up to our standards and meet all of the specifications that our customers expect. The next and final video in this series follows this 5.25” subwoofer example into enclosure assembly and final testing.